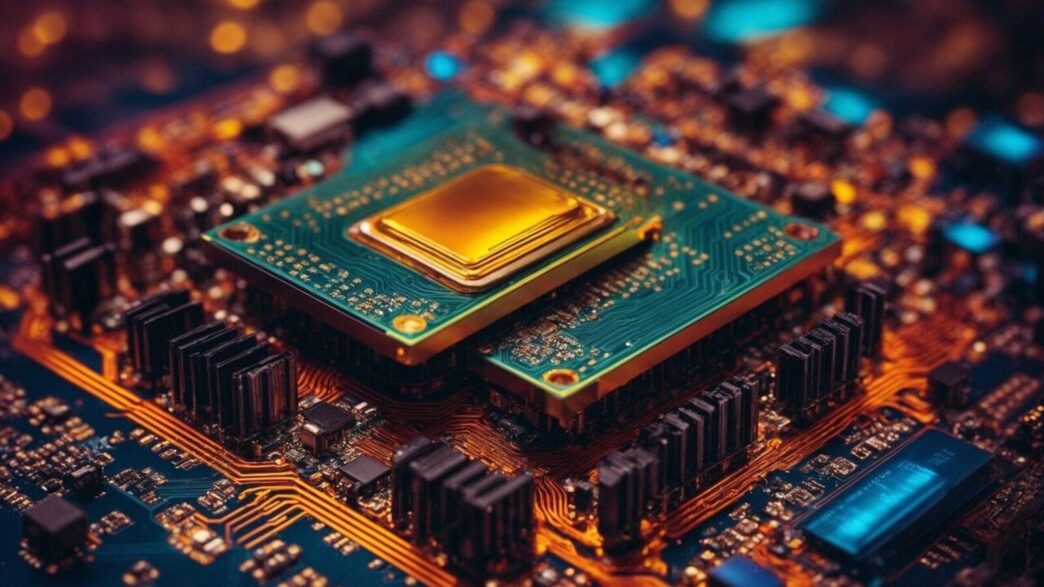

The move triggered conversations about the global semiconductor market, US dominance, the lopsided chip industry, and what would happen if the US imposed even more severe restrictions on India’s access to processors.

What would happen if India fails to procure chips?

The move would deal a significant blow to India’s large corporations across industries—not just to core technology firms. Today, silicon chips are used in nearly every industry—automobiles, energy, financial services, manufacturing, and even space. While not all of them are cutting-edge chips built by the likes of Nvidia Corp. and Qualcomm Inc., even older generation chips are largely built and designed by US tech firms. India does not have this capability yet.

Then, there is the consumer electronics industry, which is slowly but steadily capturing an increasing share of the domestic economy. In January, Mint reported that the electronics industry generated nearly $145 billion in revenue in 2024. The Centre announced that this sector could contribute $500 billion, or nearly 7%, to India’s $7 trillion economy goal by 2030. With increasing proliferation, this figure is only likely to rise and not slow down. Chips, on this note, are vital to this industry.

If such a ban happens, there will be an undoubted impact on the domestic market. Foreign investors, who have been largely bullish on India’s growth potential barring the past month’s correction of valuations, are likely to pull out of the market—leaving Indian firms potentially facing a steep decline.

Even taking inventories and global alternatives into account, there’s no denying that Indian firms would be unable to conduct free business with ample forward-looking inventory in the absence of an unrestricted semiconductor supply line.

Proof of this could be seen in the impact on Huawei during the first US-China trade war five years ago. Between 2019 and 2020, the US, during Donald Trump’s first tenure as president, imposed sanctions on the China-headquartered technology conglomerate, blaming it for spying on the US government at the Chinese government’s behest. At the time, Huawei was one of the world’s largest consumer electronics firms and was on track to overtake both Apple and Samsung to become the world’s largest technology company in consumer sales.

While Huawei survived by making its own chip through a subsidiary named HiSilicon, its market has since been decimated. Its innovations now only serve the Chinese market, as its processors no longer attract global chip designers and application developers to make them compatible with the global technology supply chain.

Does India have an antidote for this threat?

India’s biggest strength today lies in its cost differential in offering services. With significantly less expensive human and real estate resources in the country, the cost of technology services afforded by most of the top private firms in the US is well leveraged by India through its technology outsourcing firms, such as Tata Consultancy Services (TCS), Infosys, Wipro and HCL, among others.

India’s next big strength lies in its demography, making it one of the world’s most important consumer and data markets. OpenAI chief Sam Altman, for instance, called India its second-largest market outside of the US. For Mark Zuckerberg’s Facebook, Instagram and WhatsApp, and Google’s YouTube, India is either the largest or the second-largest market globally.

Experts said theoretically, India restricting market access to internet-based tech companies in the US would hurt their business prospects. Howerver, they also warned that such a move would only worsen the situation. Ajai Chowdhry, co-founder of HCL Technologies Ltd and an industry veteran, said that such moves would only lead to the “weaponization of technology” and wouldn’t serve anyone’s best interests.

However, each industry stakeholder admits that India does not have a direct answer to the US if the latter were to stop chip supplies to India.

Has India made moves to address the US’ chip leverage?

Yes. On 5 February, Mint reported that the Centre has held discussions to build and develop a dedicated semiconductor chip from the ground up, using government-affiliated agencies, researchers, academia and startups. The chip would be used in the ministry of electronics and information technology (Meity)’s national AI Mission.

This, though, is not all. India leads the world in terms of its work on chip design—nearly one of every five chip designers is of Indian origin. While they do not have core semiconductor fabrication expertise, chip design engineers can help design a range of processors and work towards patenting them—thus giving India core rights over its own-designed technology. As India starts creating more patents, its reliance on the US will wane.

To facilitate this, the Centre is working on an incentivization structure to encourage more semiconductor design in India. The next tranche of India Semiconductor Mission (ISM) approvals, too, could contribute to reducing the gap between India and the US in the semiconductor market.

How far behind is India in the global chip industry?

Semiconductor sales generated $627 billion in annual revenue in 2024 and are on track to generate $697 billion in 2025. The US accounted for over half of this revenue alone, according to consulting firm Deloitte’s annual industry outlook.

India, on this note, is estimated to account for around 4% of global semiconductor revenue—a figure achieved because of the country’s sizeable base of semiconductor chip design engineers. The US’s chip market is, therefore, nearly 13X the size and scale of India’s. But even more alarming is the geopolitical might that semiconductor supremacy gives the US.

Deloitte’s 2025 report also underlined that the combined market cap of the top 10 global chip companies was nearly $6.5 trillion. Mint’s analysis of publicly available data showed that seven of the top 10 companies are American, and 75% of this market cap belongs to them. India, to be sure, is not on this list.

Can India still catch up?

Yes, but it is a long road ahead. India is expected to operationalize its first chip fabrication factory, or fab, by the end of 2025, according to Union IT minister Ashwini Vaishnaw. Organizations such as the Centre for Development of Advanced Computing (C-Dac) are working on improving the performance of their self-designed chip cores—the key part where US companies own patents.

Chip development, however, is a prolonged story. It has taken three to five decades of research and development for most US firms to reach the current stage. Experts suggest this process will likely take much less time due to a more technologically mature and robust global ecosystem and supply chain. But, even then, making a self-designed chip and achieving cutting-edge performance with reliable stability cannot happen overnight—it would take at least two years, even at breakneck speed.

Industry consultants have urged the government to focus incentives, subsidies, and investments on developing core competencies to avoid being held a geopolitical hostage at any time in the future.